As we come to the end of 2023,

I thought it might be helpful for buyers

to understand some of the changes

the fabric industry has been,

and is, going through.

I hope this enables people to understand some of the

challenges we all face when trying to

update the decor in our homes.

Furniture manufacturers are what drives the home decorating fabric industry, not fabric stores. A fabric is produced, and shown to the different fabric companies, and it is their reaction to that fabric that is the most important criteria for the production of it. Did it sell well to them? Or was their reaction a no go. The importance of this is, this is what dictates how long a fabric pattern might be in production. Note the word might.

While the home decorating fabric companies did well during Covid, many have struggled since then. The industry has been impacted by covid, cotton shortages, as well as production issues. The transition from rotary printing to digital printing has add its own chaos. It impacts everything from mills to warehouses to those of us who buy fabric.

In my opinion, it is the biggest change to the industry is years. After all, there is evidence of fibers being dyed with dyes from 5000 years ago.

Less than ten years ago a few fabric companies started working with digital printing for home decorating fabrics. I recently asked a rep what percentage of the new line had been digitally printed. His answer was “100%”. This is telling. The industry has entered a new era.

In an effort to cut costs, to keep companies viable, whether one likes it or not, this is the now the industry standard.

Though not a fan of the digital printing, there are some benefits to this method of production. For the fabric companies the benefits are huge- ease of production, the ability to do short runs of a fabric, less warehouse space needed.

But, for the consumer, there are a few things that may be problematic. The largest issue I see is a fabric pattern’s longevity may be short.

It used to be that a fabric company would run a pattern for about three years. When a furniture company buys fabric for a furniture line, the fabric company guarantees it for a specific period of time. So, they might guarantee it for a year, or perhaps a bit longer. But, with the large runs of a screen printed fabric, there was usually a lot of a run sitting in warehouses.

But, with digital printing, they can guarantee continuity while doing short runs- 350 yards versus 4500 yards with screen printing. This means the fabric company can guarantee it, while not having to do the large runs. It can be produced at will, when a furniture company orders it again.

But, if they don’t reorder it, the fabric pattern could be dropped. And, it could be dropped within three months of the release date, if it does not move well. With the short runs, there might not be any of that pattern in storage. No furniture company bought 4500 yards of fabric. But, a company might buy all of a digitally printed run of 350 yards, leaving no stock at the mill.

My point? If you see a fabric you like, get it.

Other issues also are causing issues with supply, which can lead to difficulty in getting a fabric. There are some mills that are still having production issues. Some of this is due to shortages of a particular fiber- the world is into its third year of cotton shortage. Some of it is due to employee issues. Some companies that have not moved to digital printing are giving a lead time, if a fabric is not in stock, of eight months. Yes, that is right. One company we deal with says it will be eight months to get a fabric if it is not in stock. This is not for special orders, this is for fabric that is part of their line. If they are out, it is eight months from the order date to receiving it in house.

We get asked about fabrics from Days of Yore… even about fabrics from twenty years ago. Those fabrics are not going to come back.

We have fabrics printed for us. As long as the screens are in existence, we can have them printed as the original pattern was. But, as companies move to digital printing, the screens are being destroyed. Yes, the pattern might be the same, but both colors and the ground cloth used will not be. The colors differences between dyes and inks is quite noticeable. And the inks used need specific ground clothes. Most mills offer two choices. The wide range of different ground cloths from Days of Yore are gone. The beautiful Swiss cottons, the damask, jacquard basecloths, are, sadly gone.

So, again- if you see a fabric you really like, get it! Do NOT hesitate, as no one really knows how long a pattern will be available.

_____________________________

Here are a few fabrics we have that are in short supply.

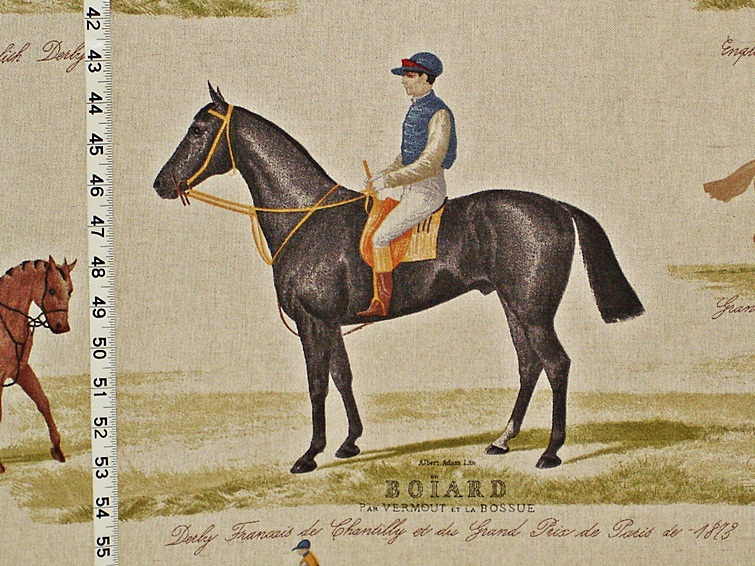

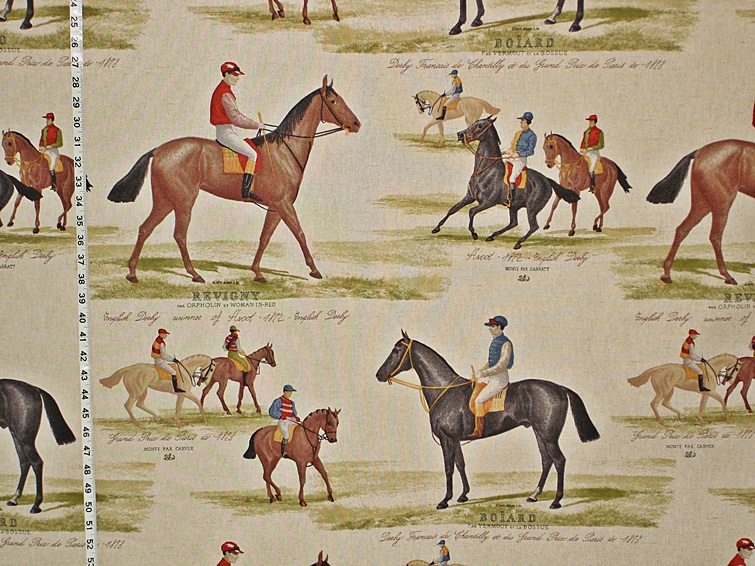

The horse racing document fabric

is a classic.

It shows horses and jockeys,

with the names of horses and races.

The Deer Silhouette fabric is

a nice nature fabric.

It has two different vignettes.

The French blue chicken fabric

is a bold rendition of a rooster toile fabric.

The French sunflower fabric

has the look of a sunflower meadow!

I love that idea.

The brown Asian crane fabric

has birds and flowers in a bamboo forest.

We have several rug fabrics.

But, the most interesting to me is

the patchwork rug fabric.

It has a medley of different designs,

with many interesting patterns.

One of the prettiest Indiennes is

the blue aqua floral indienne.

This has a linen colored background,

with soft colors punctuated by deeper tones.

The use of white, as a dye,

is unusual.

There is a bit left of each of the

Whimsical Animal fabric.

It came in green, yellow, and grey.

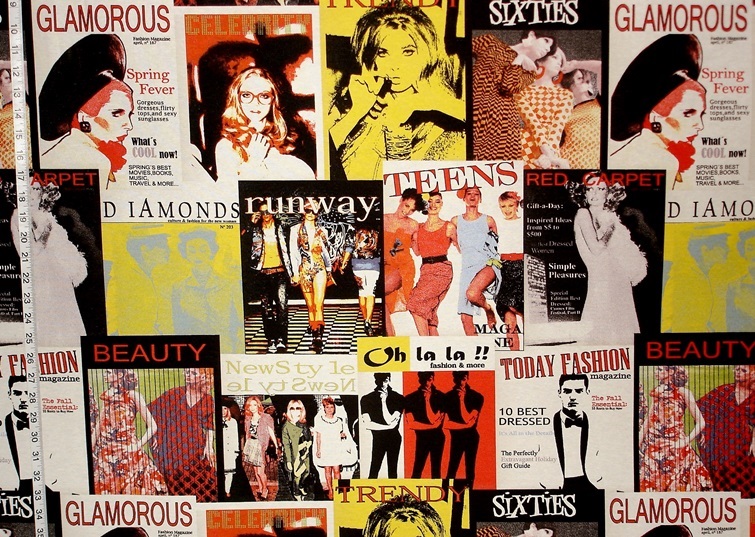

The girls’ and womens’ magazine fabric

is filled with color and pattern.

It is BOLD!

Tropo, by Clarence House,

is an embroidered silk taffeta.

We have some in purple on aqua,

pink on pink,

and blue on yellow.

Wishing all the best as we

move into 2024.

_________________________________________